A Guide To Mechanical Watch Movements

By Sarah Jayne Potter | 6 minute read

Since its invention in the early 16th Century, the mechanical watch has been sought-after and admired for the exquisite craftsmanship of its delicate internal movement. In this guide we’ll explore the long and storied history of mechanical timepieces, from the piece that started it all, through to the modern manual and automatic movements that we recognise today. We’ll also break down how a mechanical watch movement works, and discuss the benefits and maintenance required for these timepieces.

A brief history of mechanical watch movements

The ‘Nuremberg Egg’, created by Peter Henlein in 1510, is often described as the first example of a wearable timepiece. However, these early watches were notoriously inaccurate and mostly useless for keeping track of the time. Instead, they were worn as fashion items, adored by the nobility for their novelty and fine ornamentation.

During the era of the pocket watch, popularised by Charles II, there were a number of key advancements in watchmaking. The first, in around 1657, was the invention of the balance spring by British scientist Robert Hooke and Dutch physicist Christiaan Huygens, which greatly improved the accuracy of these portable timepieces. However, the modern level of precision was not possible until 1760, when John Harrison invented the marine chronometer.

The pocket watch remained in style for many centuries, until World War I called for a more practical solution for soldiers in the field. The wristwatch already existed before this time, but it was worn exclusively by wealthy women, as a decorative status symbol. With timekeeping being such a crucial aspect of strategy during the war, the wristwatch replaced the pocket watch as a more practical and hands-free option. Soon after, the watch quickly began to gain momentum in the fashion world. This opened up the market for mass production, and saw wristwatches declared a must-have luxury accessory for both men and women.

Over the years since, there have been many more advancements in watchmaking. One of the most notable is the invention of the self-winding, or automatic, watch by British watchmaker John Harwood in 1923. It would then take until the 1970s for a new technology to come into play, the quartz wristwatch.

What is a mechanical watch movement?

The watch movement, also called the ‘calibre’, is the beating heart of every timepiece. It powers all of the watches functions, from the movement of the hands to the chronograph, alarms and any other complications. A mechanical movement is made up of an intricate series of springs and gears that turn energy into precisely regulated movements. This allows the watch to run with exceptional efficiency, and accurately keep track of the passage of time.

However, for many horologists, the movement is far more than just the engine of the watch. There is an elegance and a beauty to the inner workings of a well-crafted timepiece, making it closer to a work of art than just another accessory.

Types of mechanical movements

Manual

A manual watch movement requires the wearer to manually wind the watch, usually once a day, in order for it to work. It’s the oldest and most traditional type of watch movement, and is beloved by many collectors for the expert craftsmanship involved. Manual watches will often have a transparent case-back, to show off the intricate beauty of the movement inside.

Automatic

An automatic watch movement is similar to a manual watch, but with a few important differences. An automatic timepiece winds itself whilst worn, by making use of kinetic energy. Provided the watch is worn regularly, it will maintain its power without any need for manual winding by the wearer. Automatic watches are also often thicker and heavier than their manual counterparts, due to the extra components needed to function.

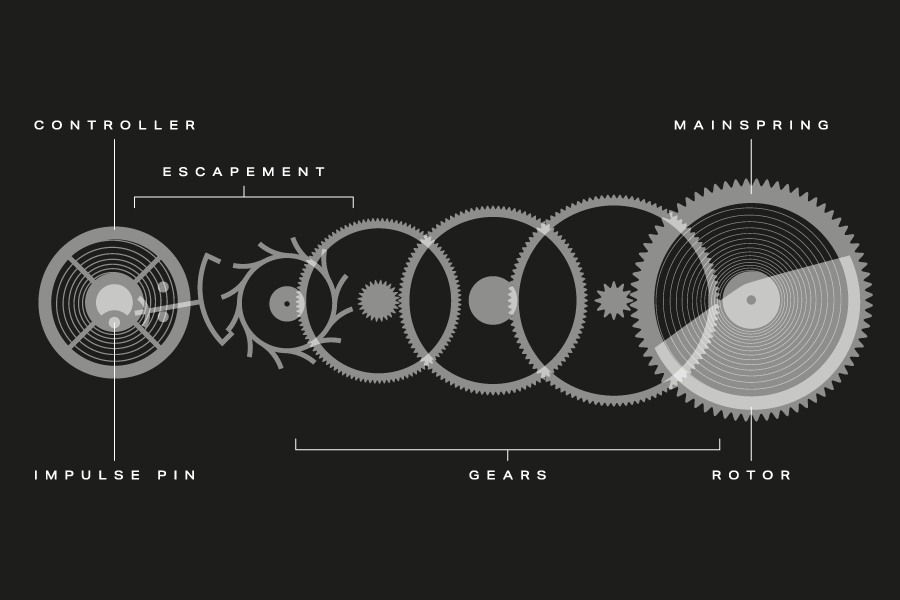

How does a mechanical watch movement work?

A mechanical movement uses kinetic energy, instead of a battery, to power the timepiece. Turning the crown produces energy, which is then transferred into the mainspring. Here, this energy is stored as the spring gets tighter, and it is then released through a series of gears and springs to power the watch’s functions and complications.

An automatic watch generates power in broadly the same way. However, it has an important extra component as it is built to take advantage of the energy generated by the motions of the wearer’s wrist. To do this, automatic watch movements use metal weights, called rotors, that spin freely within the watch each time the wearer moves their wrist. This motion is transferred into energy, which winds the mainspring automatically.

- Crown

- Mainspring

- Gear train

- Escapement

- Balance wheel

- Dial train

- Rotor

The wearer turns the wheel at the side of the watch to wind it and provide power.

The kinetic energy generated by turning the crown is transferred and stored in the coil-shaped mainspring. The tighter the spring gets, the more energy is stored, and the longer the watch can be powered for.

As the mainspring slowly unwinds, the stored energy is released through the intricate series of gears in the gear train, and into the escapement.

The escapement controls the release of energy, ensuring it is metered out in precise increments. The distinctive ticking sound a watch makes is the escapement and pallet fork at work.

The balance wheel is the heart of a watch, and allows the movement to keep regular time. The oscillations, or beats, of the balance wheel require skillful adjustment in order for the watch to run accurately.

The gears within the dial train transmit the precisely regulated energy from the balance wheel to the watch hands. This causes the hands to move at the right intervals to keep the time.

A rotor is a small metal weight which is connected to the mainspring by a number of gears. As the wearer moves their wrist, the rotor swings and winds the mainspring automatically. Once the mainspring is fully wound, the built in clutch will prevent it from winding any further.

Benefits of a mechanical watch movement

Built to Last

A beautifully crafted wristwatch is made to stand the test of time, and can last a lifetime with the proper care and maintenance.

No Batteries

With a mechanical watch, whether you choose a manual or an automatic movement, you’ll never need to worry about replacing the batteries. As long as you keep it wound, your watch will continue to keep track of time.

A Daily Ritual

Having daily rituals can be a calming influence on us, and many horologists enjoy the routine of manually winding their timepiece each day.

Aesthetics

Mechanical timepieces are a work of art. From the delicate and precisely tuned movement, to the beautifully crafted dial and bezel, a luxury watch is something to be shown off and admired.

Maintenance of a Mechanical Watch

A high-quality timepiece is something to be treasured, and it deserves to be looked after with proper care and attention. With a little extra TLC, a well-crafted watch can last for many lifetimes, and makes a wonderful heirloom to be passed down through the generations.

Get your timepiece regularly serviced

A regular, professional service is one of the best things you can do to ensure your watch is well looked after and remains in good working order. We recommend getting a mechanical watch serviced every three to five years.

Keep it clean

Get into the routine of giving your watch a wipe down each night before putting it away, and a more thorough clean every three months.

Consider proper storage

A purpose made watch box, or the original display box, are the best way to keep your watch safe whilst it’s off your wrist. A good storage box will help to protect the delicate mechanical parts, and prevent your watch from acquiring bumps, scrapes, and scratches.

Keep your watch wound

To keep your watch ticking over and running smoothly, it’s important to keep the movement running.

With an automatic watch, this is as simple as wearing it regularly. For automatic watches that are worn less often, and for manual timepieces, this means giving them a regular wind. When winding a mechanical watch, ensure you take it off and never wind whilst it’s on your wrist. This can put extra pressure on the components and damage delicate parts.